Pan-tilt mechanism research

There is a large variety of solar panel pan-tilt mechanisms. Here you can find a general overview of various solar panel tracker ideas.

SunWize has a large number of solar panel connectors and brackets. Solar Electric has pole mounts.

Potential Design One

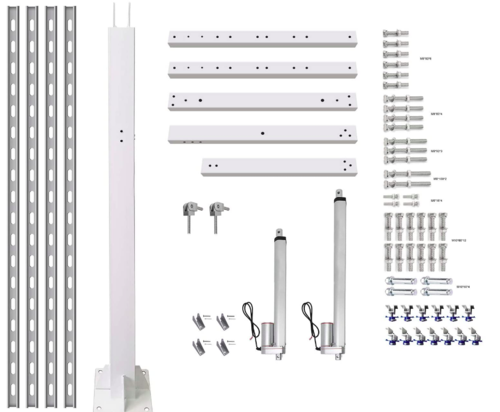

Taking inspiration from ECO-worthy linear actuator controller

This design does not have a rotational mechanism, but two linear actuators and three hinges. The hinges permit it to tilt in different directions, simulating a rotation.

Pros:

- Linear actuators can resist change in motion i.e. when you power them to a certain position, they will stay there and not consume extra power.

- Linear actuators are somewhat cheap

- All materials for this design can be bought locally, like Lowe's

- Existing template for this design exists. Maximum load with their actuator and trigonometry is 330 lbs, which is more than enough to carry five solar panels. (We don't have to calculate torque)

Cons:

- Linear actuators don't have encoders, so we would need to attach a position sensor or accelerometer to the motor.

Same linear actuators can be found on Banggood Linear actuators

Potential Design Two

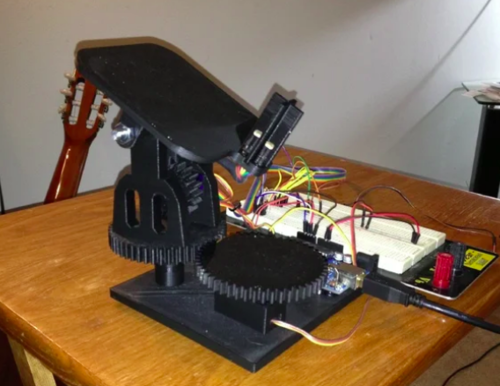

Taking inspiration from Simplified Solar Panel Pan-Tilt

This design is cute and can be completed as a benchtop experiment. We would calculate the torque to rotate our mass, and then we would program servo rotation with an Arduino. We would need someone to 3-D print the gears and send them to us.

To tilt the solar panels during the day, we could mount them to a rod and rotate the rod, similar to this mount.

Pros and possibly also cons:

- We can play around with gear ratios and design to have a super precise movement

- We have to find motors

- It would be a massive mechanical display

- We can use encoders, which would make programming easier in the long run.

Cons:

- It might require sourcing someone for CNC or lathe use

- We don't know what issues we might run into scaling up such a design